A groundbreaking partnership between Mercedes-Benz AG and Apptronic is positioned to introduce revolutionary strides in integrating robotics into automotive production. At the center of the partnership is Apollo, a humanoid robot specifically designed to adapt to complex manufacturing processes often associated with various parts of the automotive industry.

The partnership makes use of the specializations of both parties.

The extensive experience of Mercedes-Benz in the field of automotive manufacturing serves as the perfect avenue for Apptronik’s cuttong-edge robotics.

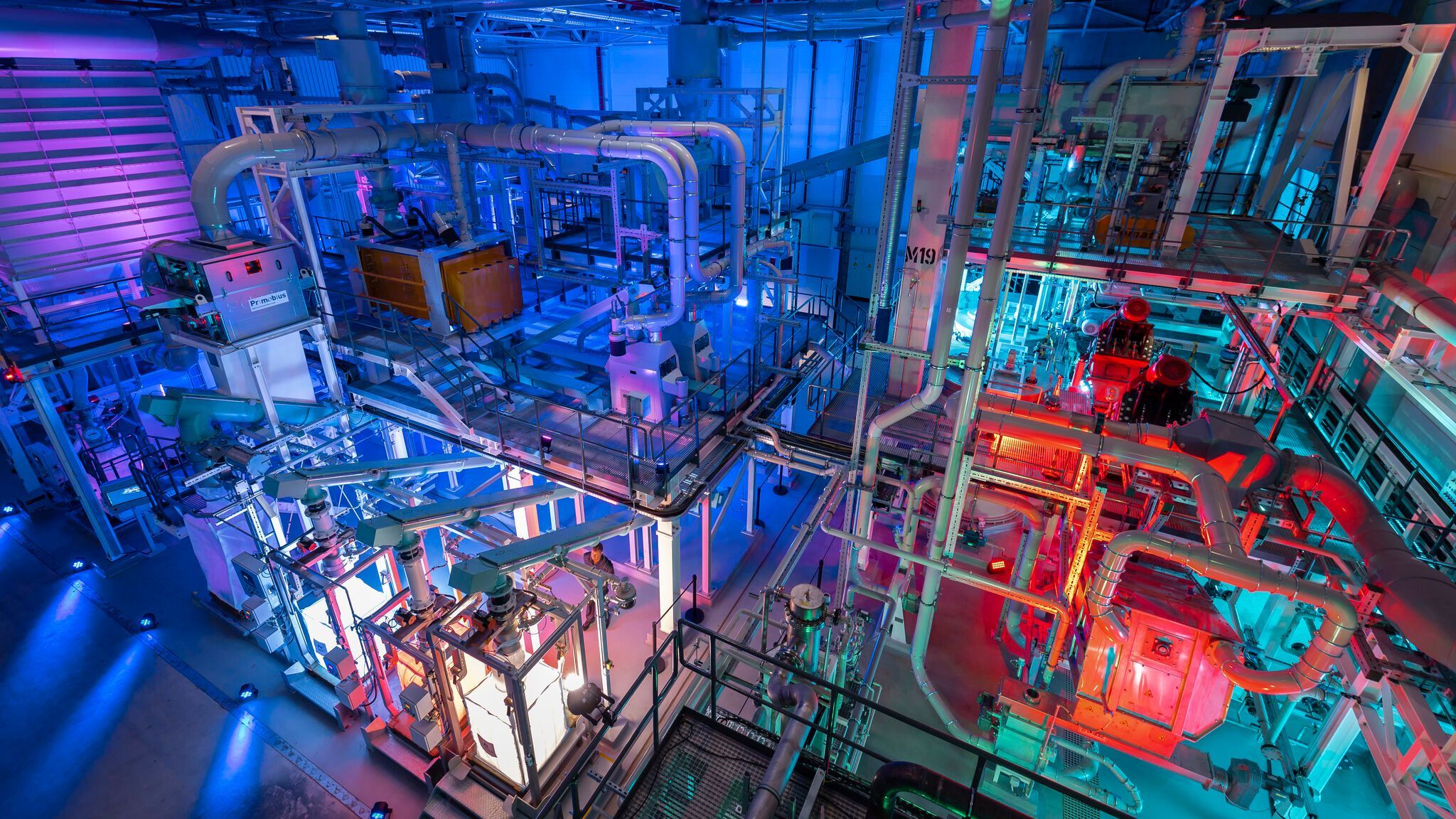

Apollo, still in development, is undergoing rigorous trials in Apptronik’s Austin Lab where the robot is receiving training to be capable of adapting to real-world production pipelines. When fully-developed, Apollo’s introduction to the Mercedes-Benz production network can mark a significant upgrade to the efficiency and automation of manufacturing lines.

Thanks to Apptronik’s technological prowess, Apollo is designed to handle complex tasks and adapt to dynamically-changing environments. Its training is designed to help Apollo maintain precision and safety and improve productivity while working with its human counterparts.

Proving The Benefit Of Combining Fields

Apollo’s development isn’t just the result of an ordinary collaboration, but is rather proof that the combination of vastly different fields can provide vast benefits to society. From the perspective of Mercedes-Benz, Apollo can improve the sustainability and efficiency of their manufacturing pipeline. For Apptronik, the partnership can help them refine and test technologies in the dynamic setting of automotives and even potentially develop the next generation of manufacturing robots.

This innovative approach allows both companies to gain a competitive edge against their industry counterparts. Moreover, seamlessly integrating advanced robotics into workflows can set a new golden standard for global manufacturing practices.

A Win For Society

As Apollo paves the way for robots to take on more physically demanding and repetitive tasks, this will hopefully open the road for humans to take on more strategic, creative, and supervisory positions that will create more fulfilling and safer working environments.

Moreover, Apollo’s integration underscores the two companies’ broader commitment to sustainable innovation. Creating more adaptable production pipelines with automated processes involving robots like Apollo means using less resources, allowing industries like automotives to become more eco-friendly.

The Road Ahead

Although the Mercedes-Benz and Apptronik partnership initially provides them advantages in their specific fields, Apollo’s successful rollout will mark a significant step towards the harmonious coexistence of human ingenuity and robotic precision. Apollo being integrated into the Mercedes-Benz production pipeline will introduce a never-before-seen mass-application of robotics into a complex real-world environment.

At the end of this collaboration, the milestones achieve will likely inspire other teams to work and introduce even more advancements in robotics and automation. As the world looks at Apollo as a prime example of such a groundbreaking initiative, Mercedes-Benz and Apptronik now have the opportunity to set an example of how innovative technologies can drive industries to success.